Combining Infrastructure Data with Lutra's Engineering Knowledge

Lutra are pleased to introduce our Advance Process Modules for Water & Wastewater Treatment plants!

Utilising Infrastructure Data (ID) and Lutra's process engineering know how, these process modules go a step beyond most batch reports and dashboards, providing insights to how a plant is operating, as well as providing data which can directly feed into the Network Environmental Performance Rules reporting.

Want to see some example outcomes? Check out the below:

Water Treatment Production Efficiency

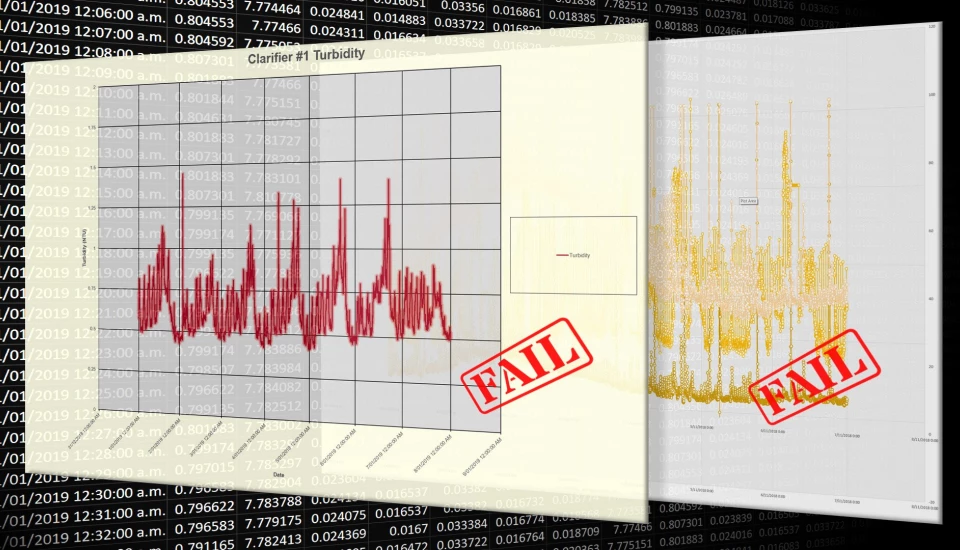

With an ever increasing pressure on operational costs (OPEX), as well as energy and water efficiency, it is important to understand where your treatment assets may or may not be operating as effectively as they could.

Lutra's engineering team have created Production Efficiency models within ID to help measure how a plant is performing, and highlighting key treatment processes which could be improved.

These are designed to match your plants treatment processes, and provide insights as to where you are potentially using excess water (i.e. backwashes), chemicals or energy to treat water. They can also highlight when a plant is reaching an overload point (i.e. solids entering the plant), giving your operations teams better, data driven guidelines to work within.

But there are more, as well as the above Lutra have developed several wastewater modules, check out the videos below where Chief Engineer Louis Ortenzio runs through their benefits.

Wastewater Advanced Process Modules

Activated Sludge Data Management

Our activated sludge module is an analytical batch report which will give good process insight while setting the goal posts for activated sludge data collection.

We can take lab data, form data and SCADA data to consistently and correctly calculate parameters such as SVI, SRT, F to M, SRT safety factor, secondary clarifier hydraulic and solids loading rates.

We then average them across the time period shown here as a week to provide analytical insights. The idea being that we embed our consulting knowledge into ID to empower our clients to make optimal decisions.

Biofilm Processes

With technologies like MABR and MBBR popping up more regularly, biofilm is becoming a more common technology for upgrades or biological intensification.

We produced a report, which can take lab data, form data or SCADA data such as total flow, pollutant concentrations, etc. and calculate surface area loading rates and surface area removal rates.

With temperature data, we can do temperature correction to normalize to a reference temperature, where separately we can account for substrate limitations in the removal rates.

If that's more complicated than you need, we can just look at removal efficiencies for pollutants like soluble BOD, soluble COD, ammonia or nitrate.

Chemical Consumption

With nutrient removal to low concentrations becoming more common, wastewater treatment plants are having to either build new plants, retrofit chemical dosing, or dose more chemical to achieve effluent nitrogen and phosphorus limits.

So Lutra developed this batch report that can take form data or SCADA data such as flow meter, totalisers, tank levels, etc. to consistently and accurately calculate daily, weekly, monthly or annual chemical consumption across a wastewater treatment plant such as alum, acetic acid or caustic soda.

We can then apply unit cost to calculate overall opex and cost per cubic meter, to help you understand whether you are dosing chemical in a cost-effective way and catch any drifts in efficiency.